Failure analysis is a crucial tool when something goes wrong either in field at the hands of your customer or during reliability or validation testing in R&D phase. In failure analysis the cause for a failure is analysed. Why is it crucial? Because without proper failure analysis it is impossible to know why a failure occurred, what are the product’s weakest points are, is the failure important, and how to improve the product and fix the failures.

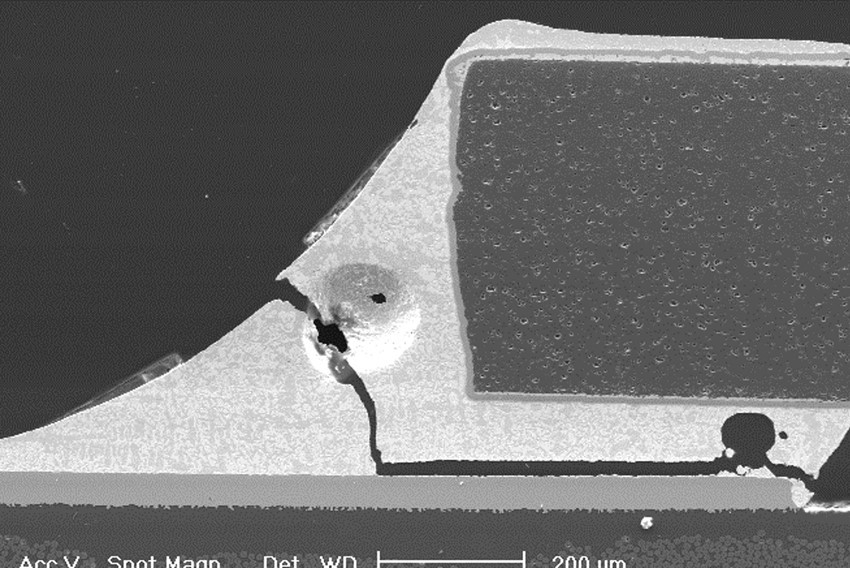

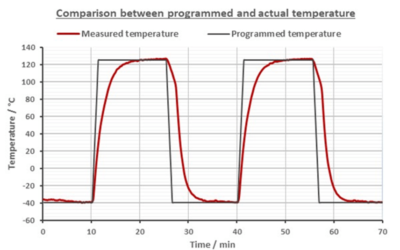

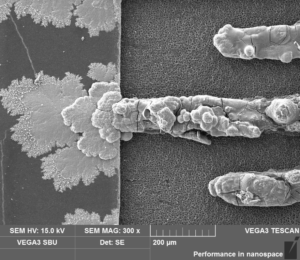

Failure analysis can be done with several analysis methods, depending on the failed structure, test method used, and type of the failure seen. The methods vary from simple visual examination and dismantling to very complicated methods. In electronics, commonly used methods are for example visual examination, electrical measurements, x-ray or cross-sections combined with various microscopy techniques. In failures regarding materials, chemical and material analysis methods are often helpful.

Personally, I have always liked failure analysis. It is a bit like being a detective, trying to find information about the failure and what caused it. It is very rewarding to be able to help your customer by showing a cause for their problem. Failure analysis can – however – be very challenging. It requires a lot of expertise to find the best methods to study the failure and a systematic study is needed to really understand the reasons for failures.

Personally, I have always liked failure analysis. It is a bit like being a detective, trying to find information about the failure and what caused it. It is very rewarding to be able to help your customer by showing a cause for their problem. Failure analysis can – however – be very challenging. It requires a lot of expertise to find the best methods to study the failure and a systematic study is needed to really understand the reasons for failures.

Failure analysis can also be frustrating, if no reason for the failure can be found or if the failure can be seen but not explained. For example, sometimes even after several different methods it is impossible to say what is the origin and what is the cause for the failure seen. Nevertheless, it is always beneficial to conduct failure analysis, because without it the behaviour leading to failures cannot be understood.