So why is the degree of cure so important?

The properties of polymers may greatly depend on the curing degree. Additionally, it is not always easy to tell without additional studies whether the curing degree of a material is high enough. They can seem to be rigid and cured, even though their curing degree is low. Low curing degree may cause several problems in use conditions. For example, the mechanical properties and the adhesion strength of an undercured material may be poor and cause failures. Additionally, the polymer material may absorb lots of moisture which, again, can cause failures. Consequently, it is important to be sure that the degree of cure is high enough.

Typically, manufactures give one or a few possible curing profiles which can be used to reach the properties given in the data sheet. However, sometimes the suggested curing profiles are not feasible for processing. In such case, it beneficial to know that quite often curing can also be conducted at lower temperatures by using a longer time or at higher temperature using a shorter time. Often the compound may even cure at the room temperature which can be very beneficial in many applications. However, when the curing profile is changed, it is critical to confirm that it does not have negative effects on the properties.

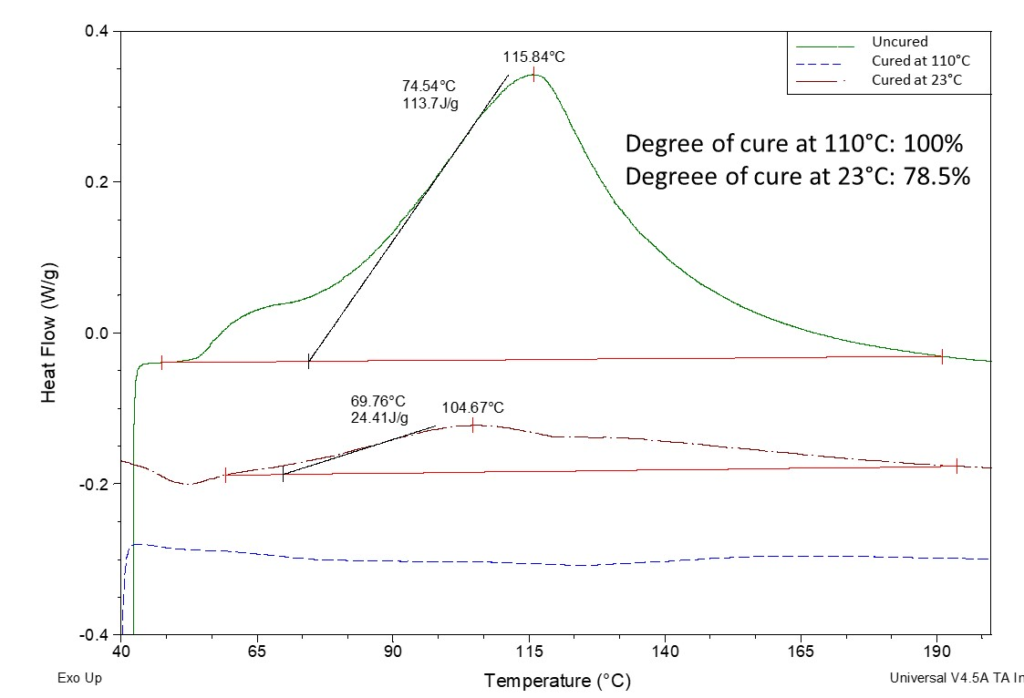

We often work with applications in which low temperature curing is vital. In these cases, it is important to check at how low temperatures the material can be cured and does the curing profile affect the properties. Checking the curing situation is actually quite easy using a Differential Scanning Calorimeter (DSC). In the picture below you can see an example of DSC curves for an adhesive material which has been cured both at room temperature and at 110°C.

With DSC we can check the degree of cure and, additionally, the temperature range at which the curing occurs. To do this we only need one small sample of fresh material and another of the cured material. This information can be used to find a suitable curing profile or to check if the degree of cure is high enough. At the same time, we can get other useful information, for example, the glass transition temperature (Tg) of the material. To analyse mechanical properties, other test methods such as adhesion or tensile testing, can be used.

The curing degree does not need to be 100% to be high enough. But what is high enough curing degree? The right answer depends on the material. Higher curing degree improves the properties of the material, but at some level this improvement slows down and finally levels off. As a rule of thumb, 80-90% is often high enough and often even less than this is acceptable. However, in critical applications it is a good idea to measure the important properties after curing to ensure that the curing profile is suitable.