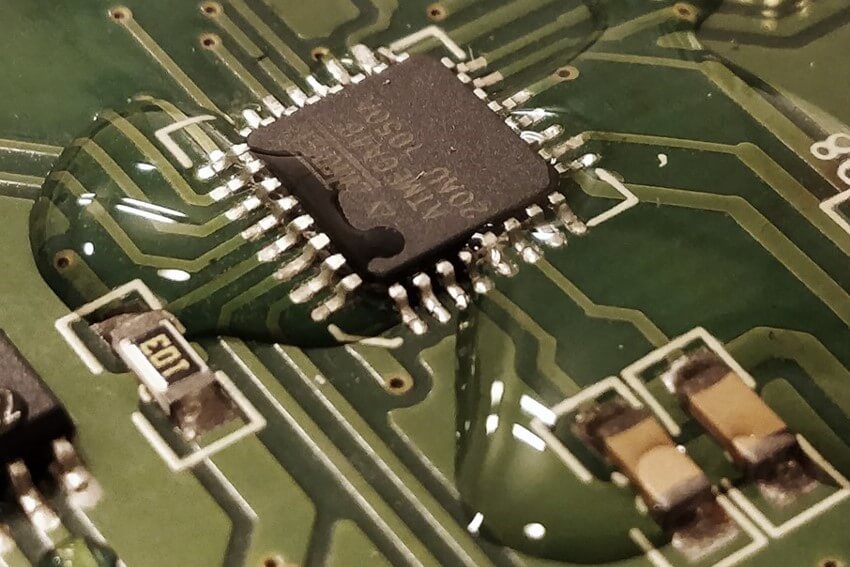

You may have noticed that more and more devices are given IP rating nowadays. For example, many handheld devices, like mobile phones, are given IP67 rating. Have you ever considered what these ratings mean in practice and how devices are tested? Moreover, would your product benefit of IP classification? Here are a few words about IP tests.

IP code, short from ingress protection, rates the protection a casing or enclosure gives against intrusions such as dust and water. IP rating is usually marked with two numbers, just like the previously mentioned IP67. The first number describes dust tightness and the second number water tightness. There may also be some extra markings after these numbers. For example, in IPX6K the letter K refers to high pressure used in water jet tests.

Dust tightness

Let us first take a closer look at the first number describing the dust tightness. To do this, the second number for water tightness is being described commonly with a letter “X”. Casings with ratings from IP1X to IP4X are not dust tight at all and in these cases the IP rating is telling more about safety of the device. This means that the number describes the size of an object which is not allowed to enter the casing or enclosure. From IP4X onwards a probe with a diameter of 1.0mm is not allowed to enter the enclosure. Below this rating the allowed diameter is greater. We can also think this the other way around. For example, if the diameter of your fingertip is more than 12mm or the length is less than 80mm, enclosures from IP2X rating onward should be safe for you to handle.

Dust tightness comes along with IP5X and IP6X ratings. The difference between these two classifications is that IP6X test is conducted for an underpressurised device, while IP5X is conducted without underpressure. In use conditions underpressure may form inside an enclosure or casing, for example during a temperature decrease or due to a change of atmospheric conditions. Both tests are conducted with talc powder in a dust chamber and test duration varies from two to eight hours.

Water tightness

While the first letter with different limits for dust and larger objects was straightforward, the second number describing water protection classification has more variation in it. Again, let us concentrate on the second number describing water tightness, while the first number for dust tightness is being described commonly with a letter “X”. IPX1, IPX2, and IPX3 enclosures are protected from water dropping from various angles. The tested angles are 0° angle (straight from above), 15° angle, and 60° angle. The amount of water is quite low in these tests, 1mm and 3mm rainfall for IPX1 and IPX2, and 0.7 litres per minute per hole in IPX3. IPX4, on the other hand, is protected from water splashed from any direction. There is a special test equipment available for each classification test.

IPX5 and IPX6 are ratings for protection from water jets. First one is conducted with water stream of 12 litres per minute, while the second one is for powerful water stream with 100 litres per minute. Moreover, a newcomer, IPX9K classification is also for water jets. This harsh classification refers to powerful water jets with hot water.

IPX7 and IPX8 are water immersion tests. In both tests the device is immersed into water in at least 1m depth. In IPX7 test the test duration is 30 minutes, while in IPX8 the test duration and immersion depths are agreed based on the real operational profile of the device.

It should be noted that in case of water tightness, the higher rating does not automatically cover the lower ratings. For example, if a device gives you IPX7 rating for water immersion, it does not automatically mean that the device would also be protected from water jets, as during water jet tests the pressure on the surface and sealings may cause enclosure leakages. Therefore, for protection against stream and immersion, a device should be marked for example IPX5/IPX7.

With IPX7 or IPX8 enclosure you can drop your phone even to salty water without a heart attack, at least if the device is new. As IP tests are conducted for brand new devices, the rating may decrease for a device that has been used for a while. For example, due to temperature and humidity exposure, the device sealings are likely to degrade during the operation of the device. Therefore, IP rating does not tell you anything about long term reliability of a product.

With IPX7 or IPX8 enclosure you can drop your phone even to salty water without a heart attack, at least if the device is new. As IP tests are conducted for brand new devices, the rating may decrease for a device that has been used for a while. For example, due to temperature and humidity exposure, the device sealings are likely to degrade during the operation of the device. Therefore, IP rating does not tell you anything about long term reliability of a product.

If you want to discuss more about IP testing, reliability testing or long-term reliability of your products, do not hesitate to contact us at info@trelic.fi