Flexible electronics means applications build with flexible substrates and materials, enabling bending and stretching of the applications. Therefore products which would not be possible with traditional electronics can be accomplished. Application such as wearable and medical electronics and flexible displays have unique structures and features compared to traditional electronics, which makes them highly attractive for many products.

Since flexible and stretchable structures are still new, there is a limited number of test standards and methods available. However, there are a few important and useful factors to consider when testing these structures. For example we always recommend measuring the electrical behaviour of the tested structure in real-time during testing. This is the only way to actually learn how the tested structures are functioning in certain environments and under certain stresses.

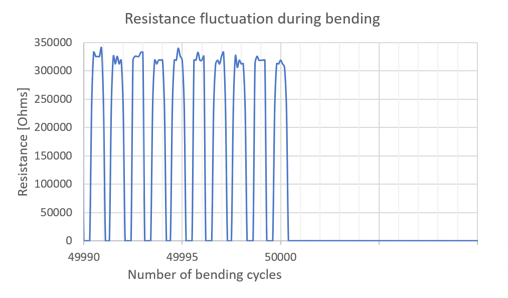

Quite often samples are not functional during testing. However, when they are returned to ambient conditions, their behaviour reverts to normal. In these cases, if intermittent measurements done only before and after testing, they give misleading results, as the failures in the test conditions are not revealed. This applies especially to bendable and stretchable structures.

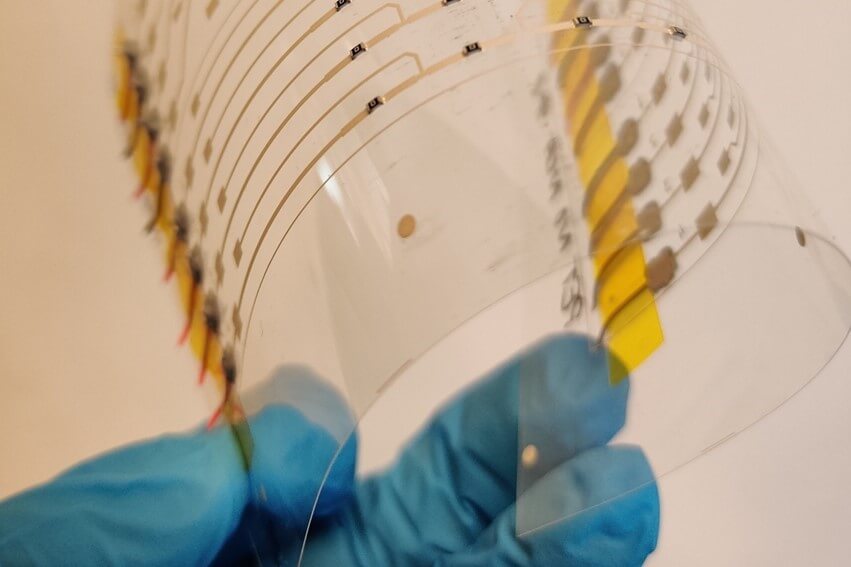

Below you can see the resistance behaviour under bending for a printed structure we have worked with in Smart2Go Eu-project. The sample consists of printed silver wires on PET film and dummy resistor components attached with silver paste (or isotropically conductive adhesive). The figure shows that during each cycle of the test, the sample has either very low resistance or extremely high resistance – basically an open circuit – depending on the severity of the bending. In this case each bending cycle was recorded with ten data points. When the structure is bent, it loses electrical contact, but when the sample is straightened, the resistance value is normal, in this case approximately 10 Ohms. This behaviour started at cycle one and lasted for the entire test. And, when the bending test was finished after 50.000 cycles and the sample was in straight position, the resistance was again 10 Ohms.

Why could this be a problem? Well, it may not be a problem for the sample, if it is not bent in its real use, or if bending is occasional and losing contact is acceptable. However, if the sample is repeatedly bent during its use, it is vital to be aware that the sample may not be functional at all positions. For example, if this would be a wearable electronics device, the electrical functionality may be lost when a person bends his or her arm. This means that the product abruptly stops functioning properly.

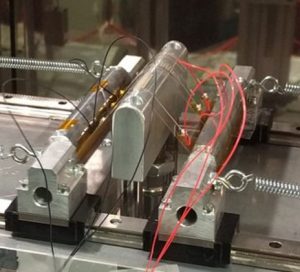

We provide testing services for the reliability testing of flexible and stretchable electronics. We have three testers designed especially for flexible and stretchable structures. Two of these testers are dynamic three-point-bending testers shown in the figure above. One is designed for dynamic twisting. We offer also a possibility to combine bending testing with high humidity and high temperature environments.