After months of sweat, tears and long hours, the newest creation of your R&D is about to be ready! There’s one more thing to do: check its functionality with reliability testing! Then maybe do some slight changes to the prototype and off we go to production!

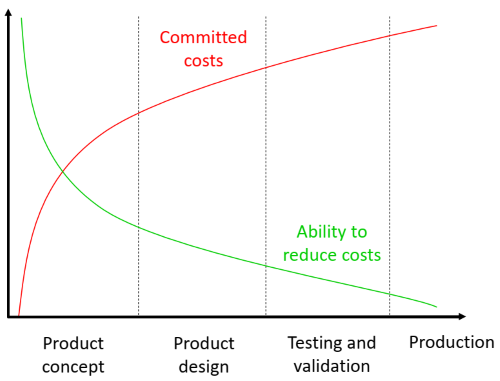

Or – should you have checked the reliability already earlier? Why? The picture below shows why.

To succeed in today’s competitive market, companies need to consider customers’ requirements for product quality and performance while, at the same time, minimizing time-to-market and product costs. Additionally, companies have to make sure that their products operate correctly not only at the end of the manufacturing line but also after transportation and storage and, of course, in the service conditions of their customers.

The worst case is, that reliability problems are observed in the field by your customers. This usually results in high warranty costs, expenses due to possible customer downtime, repairs and retrofits, customer defections, loss of reputation, and lawsuits.

This can be avoided by analyzing the reliability early enough during product development. This can be done by performing reliability tests to find out the weakest links in designs, to make the product more robust, and to obtain statistical data for lifetime analysis. However, quite often reliability and validation tests are only considered at the end of product development, just before production launch. The risk in this is that due to the decisions made earlier during the product concept and design phase, 60 % to 80 % of the total costs may already be committed at this stage. Therefore, investigating and fixing possible reliability problems and retesting the product will cause substantial additional expenses and delays in the product development cycle.

The relationship between the committed costs and the ability to reduce overall expenses during product development is illustrated in the picture above. As shown, the decisions made during the product concept phase will often have the biggest impact on the committed costs later on. Therefore, knowledge of customer expectations, how and where the product is used, and reliability requirements should be considered already from the start of the product life cycle.

In other words – To save money, please consider the reliability of your product as early as possible!