by Sanna Lahokallio | May 5, 2020 | Infographic, Materials, Polymers

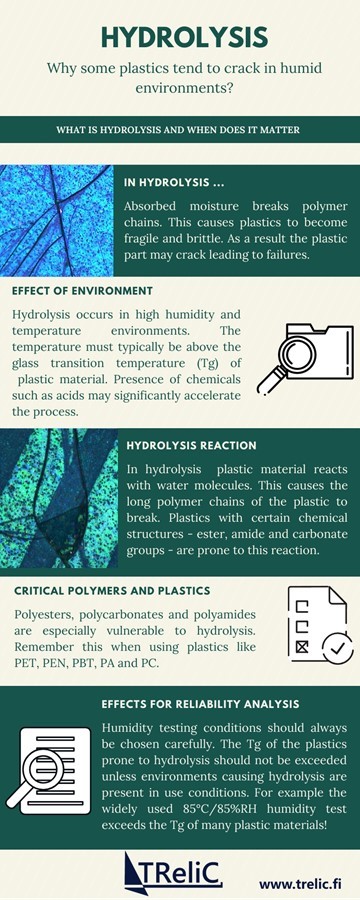

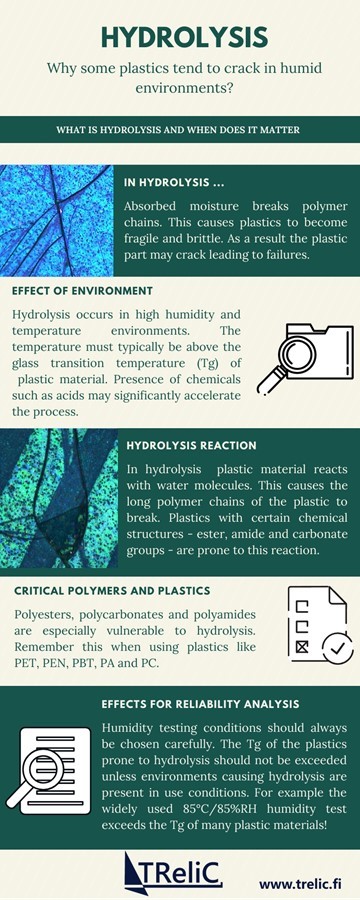

One common factor causing failures in humid environments is a phenomenon called hydrolysis. In hydrolysis moisture attacks polymer chains and breaks them. This causes the material to become brittle and usually leads to cracking of the material.

Check out this infographic about hydrolysis. What is is, when does it occur and which plastics are especially prone to it!

by Sanna Lahokallio | Oct 21, 2019 | Electrically Conductive Adhesives, Flexible electronics, Reliability, Testing

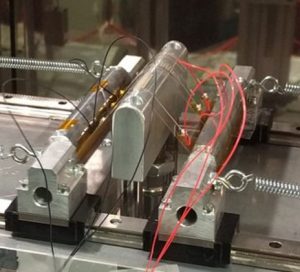

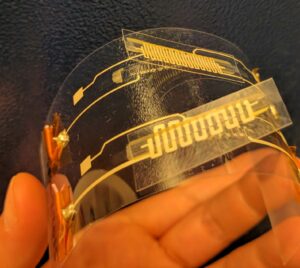

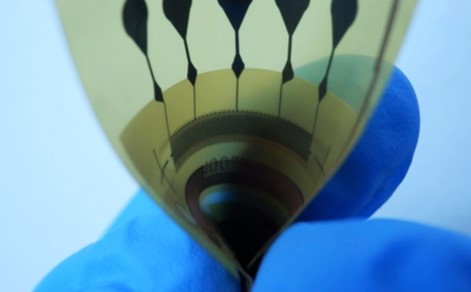

As a part of Smart2Go and our own combinatory stretch and bend tester projects, we have been doing bending testing for flex-to-flex (FOF) attachments. Bending tests and other mechanical test methods are extremely important in dynamic flex applications, since a product can be bent thousands or even million times during its lifetime.

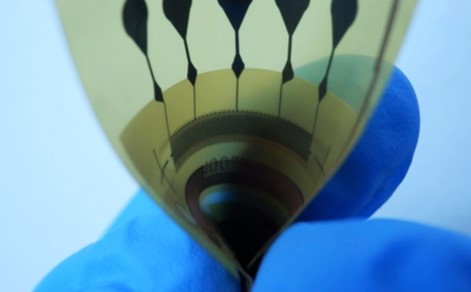

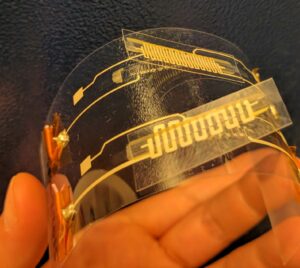

Our test structure consists of two silver-printed structures on PET film. The films were attached together using several different anisotropically conductive adhesive films (ACFs). Some of the ACFs were especially designed for flex attachments, some were good-quality adhesives we tend to use in various selection of attachments. Some of the ACFs were epoxy-based, others acrylic-based. More information about electrically conductive adhesives can be found for example here.

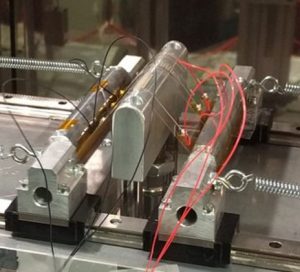

Cyclic bending tester

The test structures were bent up to 100 000 cycles at ambient conditions as shown in the figure below. Resistance of the structure was measured in real-time to capture any changes in the electrical behaviour of the structures during testing. As the figure shows, samples were tested both adjacent and perpendicular to the bending tool.

According to the test results, epoxy-based ACFs may not be the most suitable materials for flexible structures if they are exposed to several bending cycles during their use life: all our epoxy samples failed much quicker compared to acrylic-based samples in bending testing!

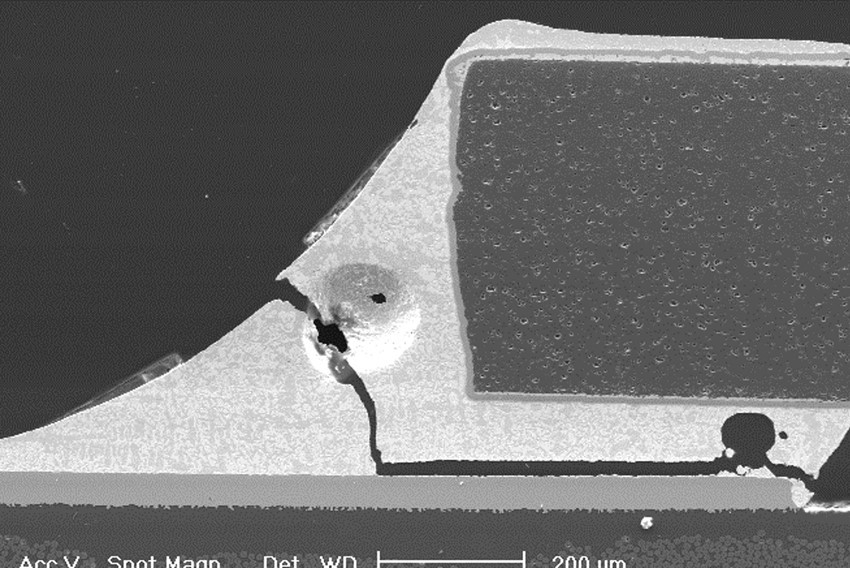

The results are not that surprising considering how much less flexible epoxies typically are compared to acrylics! The figure below shows an example of perpendicular samples after bending test: the FOF joint has quite clearly lost adhesion. Even though epoxies do not seem to be good for bending applications, it is good to remember that in many other applications they are superior to acrylics and, therefore, careful consideration of adhesives should always be conducted.

Failed FOF sample after cyclic bending test

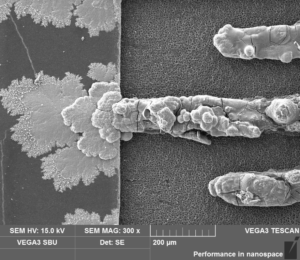

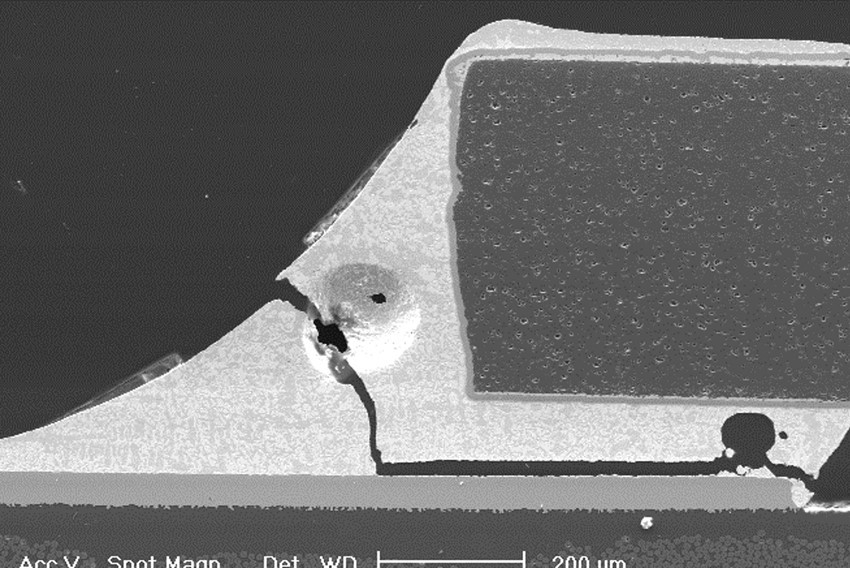

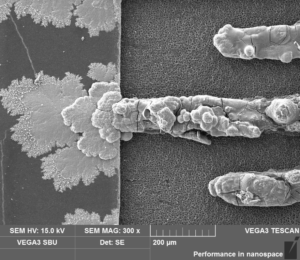

by Sanna Lahokallio | May 7, 2019 | Failure Analysis

Failure analysis is a crucial tool when something goes wrong either in field at the hands of your customer or during reliability or validation testing in R&D phase. In failure analysis the cause for a failure is analysed. Why is it crucial? Because without proper failure analysis it is impossible to know why a failure occurred, what are the product’s weakest points are, is the failure important, and how to improve the product and fix the failures.

Failure analysis can be done with several analysis methods, depending on the failed structure, test method used, and type of the failure seen. The methods vary from simple visual examination and dismantling to very complicated methods. In electronics, commonly used methods are for example visual examination, electrical measurements, x-ray or cross-sections combined with various microscopy techniques. In failures regarding materials, chemical and material analysis methods are often helpful.

Personally, I have always liked failure analysis. It is a bit like being a detective, trying to find information about the failure and what caused it. It is very rewarding to be able to help your customer by showing a cause for their problem. Failure analysis can – however – be very challenging. It requires a lot of expertise to find the best methods to study the failure and a systematic study is needed to really understand the reasons for failures.

Personally, I have always liked failure analysis. It is a bit like being a detective, trying to find information about the failure and what caused it. It is very rewarding to be able to help your customer by showing a cause for their problem. Failure analysis can – however – be very challenging. It requires a lot of expertise to find the best methods to study the failure and a systematic study is needed to really understand the reasons for failures.

Failure analysis can also be frustrating, if no reason for the failure can be found or if the failure can be seen but not explained. For example, sometimes even after several different methods it is impossible to say what is the origin and what is the cause for the failure seen. Nevertheless, it is always beneficial to conduct failure analysis, because without it the behaviour leading to failures cannot be understood.

by Sanna Lahokallio | Apr 4, 2019 | Flexible electronics, Reliability, Testing

Application such as wearable and medical electronics and flexible displays have unique structures compared to traditional electronics – they tend to implement novel flexible and stretchable structures and materials. These structures enable completely new and interesting products, but reliability and functionality testing-wise there are some obstacles. Many of these products are used in demanding environments or in applications related to safety of the user. Consequently, new test methods designed for these structures are needed to ensure their reliability.

We are currently developing a tester called FlexStress Dynamic, which combines dynamic mechanical stresses with environmental stresses. The development is funded by European Regional Development Fund (ERDF). The tester enables combinatory testing of flexible and stretchable structures by combining mechanical stress with environmental conditions such as high temperature and humidity.

Why do we want to build a tester which combines mechanical and environmental stresses? Because in real life conditions products are facing both of these factors simulatenously. If a structure is bended at laboratory environment, it behaves differently than when it is bended in humid conditions. Therefore, bending testing without environmental exposure may give much too optimistic results and thereby not reveal important reliability issues. This is vitally important, especially, when the reliability of new polymer-based structures is tested. Polymers are widely used in flexible and stretchable applications and they may be very vulnerable to conditions combining mechanical and environmental stressors.

We are not planning to expand our business to building testers, but we wanted to build the tester to be able to help our customers by offering test methods specified for the needs of flexible and stretchable structures. Currently we are testing our smaller tester and building another tester which can be used inside a humidity chamber. Service for FlexStress Dynamic will be available during this spring! Sanna, Laura and the small tester are going to travel to IDTechEx Show exhibition held in Berlin on April 10-11. Please come to meet us and the tester to talk more about your testing needs!

by Sanna Lahokallio | Mar 15, 2019 | Accelerated Testing, Infographic, Reliability

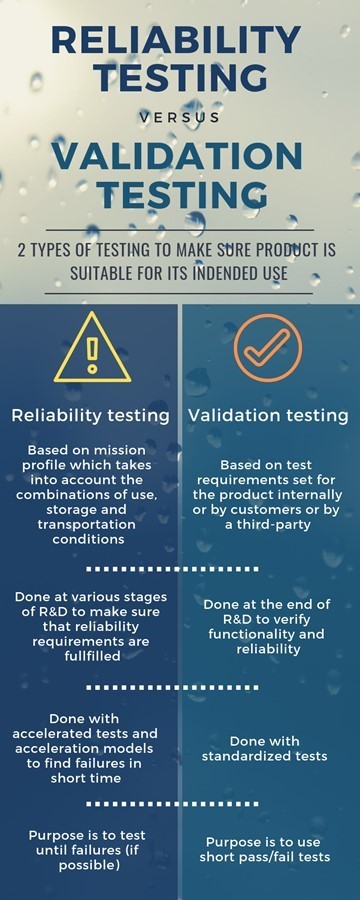

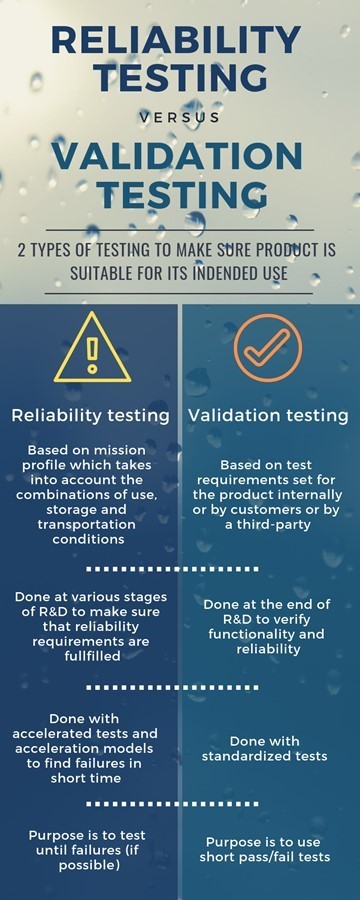

Reliability testing can be a mess when it comes to terminology. A good example is the difference between reliability and validation testing. Both are needed, but they serve different purposes. Below you can find a simple infographic about the differences between these two.

Personally, I have always liked failure analysis. It is a bit like being a detective, trying to find information about the failure and what caused it. It is very rewarding to be able to help your customer by showing a cause for their problem. Failure analysis can – however – be very challenging. It requires a lot of expertise to find the best methods to study the failure and a systematic study is needed to really understand the reasons for failures.

Personally, I have always liked failure analysis. It is a bit like being a detective, trying to find information about the failure and what caused it. It is very rewarding to be able to help your customer by showing a cause for their problem. Failure analysis can – however – be very challenging. It requires a lot of expertise to find the best methods to study the failure and a systematic study is needed to really understand the reasons for failures.

Recent Comments